Mini-ITX boards: Advantages and Disadvantages of Industrial Use

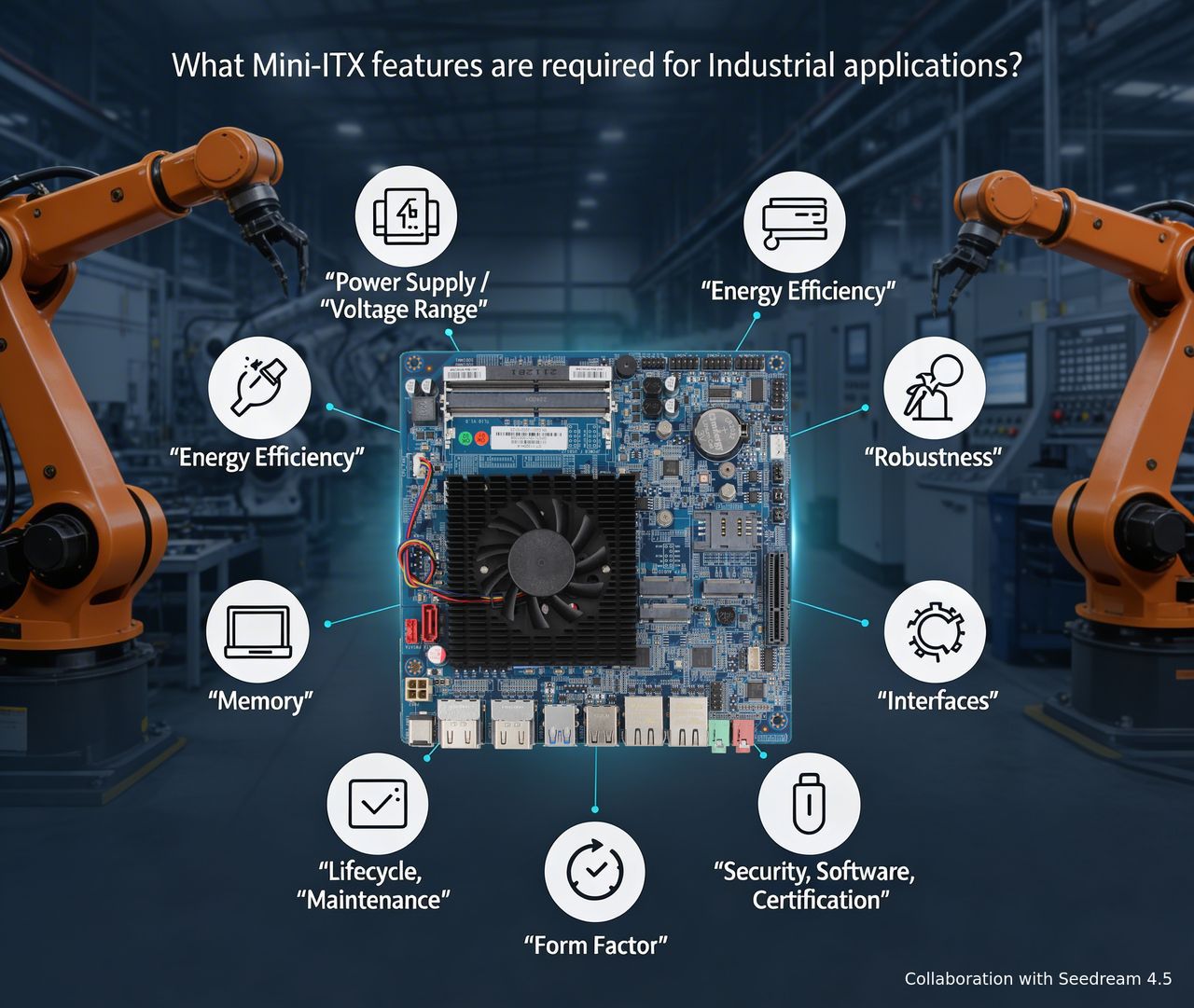

What Mini-ITX features are required for industrial applications?

Industry requirements for Mini-ITX boards

Industrial features of Mini-ITX boards

The following requirements are essential:Power Supply, Energy Efficiency, Robustness, Interfaces, Memory, Lifecycle, Maintenance, Security, Form Factor

Last updated: 19.02.2026

For industrial applications of Mini-ITX boards, certain industrial features are crucial. From an industry perspective, the following requirements are essential:

Power Supply / Voltage Range

• Wide input voltage ranges (e.g., 9–36 V, 12–24 V, 18–36 V) for direct connection to vehicle electrical systems, battery systems, or industrial 24 V power supplies.

• Integrated DC-DC converters with protection functions (overvoltage, undervoltage, reverse polarity, short circuit).

• Support for power profiles of different CPUs (T/TE/embedded variants), often with a configurable TDP limit in the BIOS.

• Support for always-on/ignition functions (e.g., in vehicles), time-delayed power on/off.

Energy Efficiency

• Selection of CPUs with different TDP classes (e.g., 6–15 W, 25 W, 35 W) to suit the application.

• Optimized voltage regulator modules (VRMs) for continuous 24/7 operation and low power consumption.

• Option for fanless operation with a large heatsink or case cooling design (heat spreader, heat pipe).

• Power management features: deep sleep states, Wake-on-LAN, Wake-on-Timer, and RTC wake for low-energy standby modes.

Robustness

• Extended temperature ranges (e.g., -20 to +70 °C or -40 to +85 °C).

• Protection against vibration and shock (reinforced solder joints, screw-locked connectors, soldered RAM/Flash where required).

• Partial conformal coating (protective lacquer) against moisture, dust, and salty air.

• Long 24/7 continuous operation with specified MTBF, suitable for continuous loads in industrial environments.

Interfaces

• Multiple Gigabit Ethernet ports (some PoE-enabled, some with TSN support for real-time networks).

• Numerous serial interfaces (RS-232/422/485) for PLCs, sensors, actuators, and legacy devices.

• Digital inputs/outputs (GPIO), relay outputs for direct control.

• Fieldbus/industrial protocols via on-board interfaces or modules (e.g., CAN, PROFIBUS, Modbus, EtherCAT via expansion).

• Multiple display outputs (LVDS/eDP/DisplayPort/HDMI) for panel PCs, HMI terminals, and digital signage.

• Internal expansion options (miniPCIe, M.2, mSATA) for WiFi/4G/5G, additional I/O cards, and SSDs.

Memory

• Support for both SO-DIMM RAM and soldered memory under shock/vibration conditions.

• Industrial-grade SSD interfaces (SATA, M.2) with support for pSLC/industrial NAND types.

• Optional eMMC or on-board flash for low-maintenance systems.

Lifecycle, Maintenance

• Long product lifecycle (typically 5–10+ years availability of the same board revision).

• Long-term availability of the CPU platform (CPU manufacturers' embedded roadmaps).

• Consistent BOM management: controlled component changes, important for regulatory approvals.

• Remote management capabilities (e.g., AMT, IPMI-like functions, out-of-band management on some industrial Mini-ITX boards).

• Easy on-site maintenance: easily accessible connectors, clearly documented pinout.

Security, Software, Certification

• Support for Secure Boot, TPM, and encryption to prevent tampering.

• Compatibility with real-time operating systems, industrial Linux distributions, and Windows IoT.

• Certifications depending on the industry (EMC standards for industrial applications, medical standards, and, where applicable, automotive standards such as E-Mark).

Form Factor

• Standardized dimensions of 170 x 170 mm, enabling easy integration into compact Box PCs, kiosks, panels, vehicles, and machines.

• Low profile, e.g., flat heat sinks, horizontal RAM modules, and low-profile connectors (important for 1U enclosures or very slim boxes).

• Mounting points: robust mounting holes, some with additional mounting points for vibration resistance.

• Front/backplane orientation of the connectors ensures optimal access to all I/Os.

Advantages of the Mini-ITX Form Factor, especially in Industrial Applications

• Very compact yet offering full x86 performance, making it ideal for edge computing, HMI panels, and compact controllers.

• Good balance between expandability (PCIe slot, M.2, miniPCIe) and footprint.

• High energy efficiency and therefore reduced cooling requirements, important in enclosed boxes or control cabinets.

• Wide range of applications: from simple IoT devices to high-performance vision systems, depending on the CPU class and expansion cards selected.

Disadvantages of the Mini-ITX Form Factor

• Due to their dimensions, Mini-ITX boards are not suitable for very small devices. Depending on the required functionality, 3.5" or 2.5" boards may be more appropriate.

• Many Mini-ITX boards available on the market only partially meet the requirements for industrial boards and are more accurately classified as "light industrial boards."

• Most manufacturers of Mini-ITX boards require minimum order quantities for economical production, which often far exceed the project volumes of their customers.

Mini ITX Boards at 1ST-embedded

Now it's your turn: get informed and use the Mini ITX Boards successful in your industrial applications!

Consult your expert: Sven Trommer

, Tel. +4940-7003550

We look forward to hearing from you!

Jelena Dronowa, Head of Digital Media, Dipl.-Ing for Systems Engineering